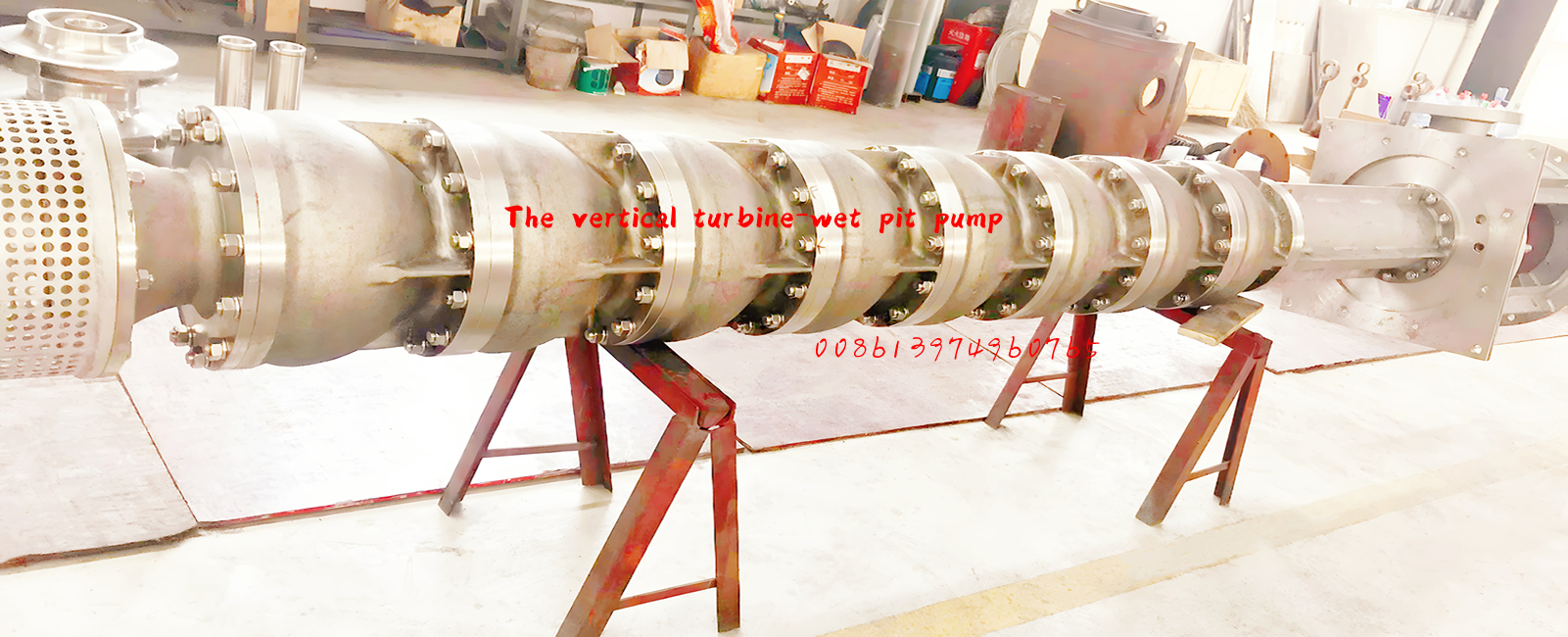

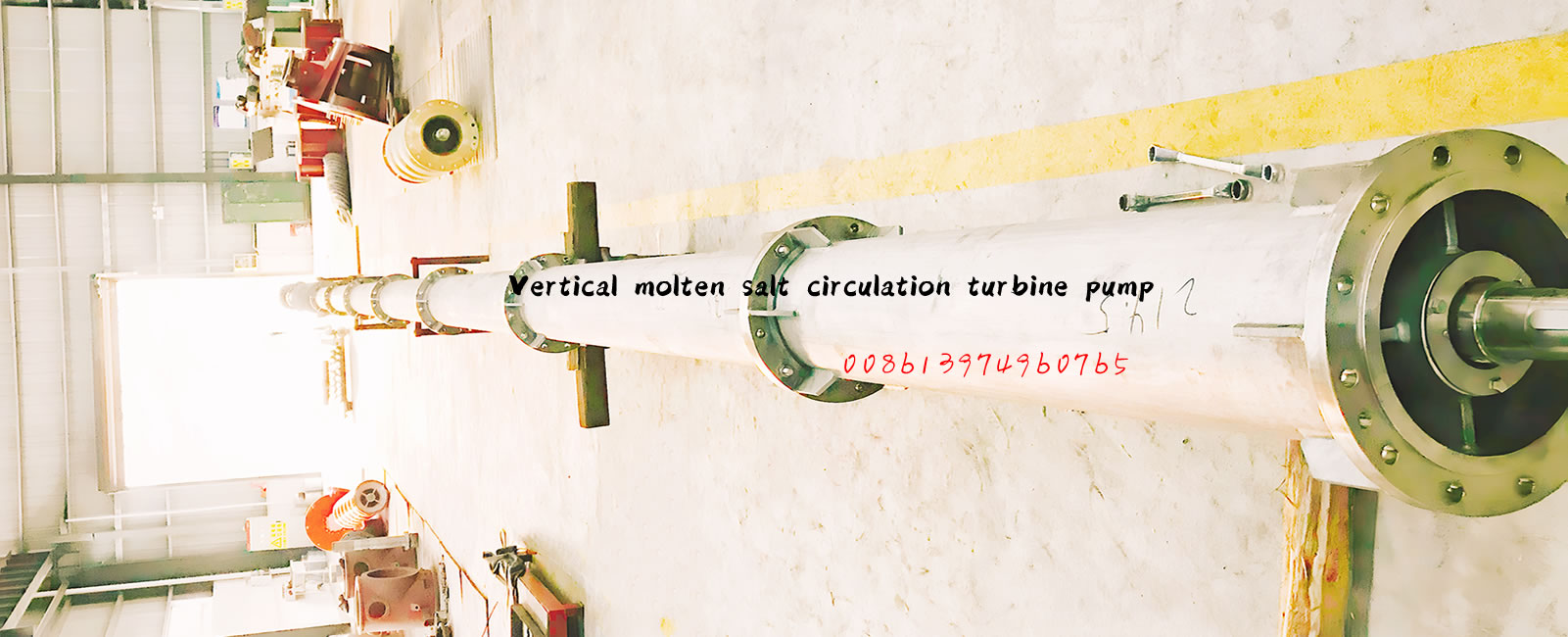

High temperature molten salt vertical Suspended semi submersible sump pump

A high-temperature molten salt vertical Suspended semi submersible sump pump, comprising a support tube nested inside a lining tube, wherein the upper end of the support tube is connected to an upper transmission device. The upper transmission device comprises a bearing body and a sealing body arranged in sequence from top to bottom, and the cooling chamber of the bearing body or/and the sealing body is equipped with a cooling mechanism; The lower end of the support tube is connected to the pump body, and the pump cover is fixed in the middle of the pump body and the support tube. The pump shaft sleeve is set in the middle of the support tube, and the support tube is used to provide an additional length of the pump body relative to the upper transmission device. When the liquid submerges the impeller of the pump body, it can be started. The reflux effect of the support tube on the high-temperature medium is used to achieve complete sealing of the high-temperature medium and prevent the overflow of high-temperature hot gas.

[Technical Introduction]

At present, vertical Suspended semi submersible sump pumps used in industries such as solar thermal power generation, valley energy storage, metallurgy, mining, environmental protection, chemical industry, light industry, and pharmaceuticals for pumping high-temperature and corrosive media often suffer from shaft holding, vibration, loud noise, and high failure rates of rolling and sliding bearings, which not only affect production but also cause certain maintenance costs. In addition, for working conditions with ultra-low installation depth, whether using traditional vertical semi submersible sump pumps or other structural types of pumps for pumping and discharging, due to sealing reasons, the reliability will be lower and the failure rate will be higher.

Technical implementation ideas

This technology proposes a high-temperature molten salt vertical Suspended semi submersible sump pump to solve the above problems. This technology is particularly suitable for high-temperature and corrosive media, and is more reliable when installed at ultra-low liquid depths, with high practical value. In order to achieve the above objectives, the present technology adopts the following technical solution: a high-temperature molten salt pump, comprising a support tube nested inside a lining tube, wherein the upper end of the support tube is connected to an upper transmission device, wherein the upper transmission device comprises a bearing body and a sealing body arranged in sequence from top to bottom, and the cooling chamber of the bearing body or/and the sealing body is provided with a cooling mechanism; The lower end of the support tube is connected to the pump body, and the pump cover is fixed in the middle of the pump body and the support tube. The pump shaft sleeve is set in the middle of the support tube, and the support tube is used to provide an additional length of the pump body relative to the upper transmission device. When the liquid submerges the impeller of the pump body, it can be started. The reflux effect of the support tube on the high-temperature medium can effectively prevent the medium from overflowing. Furthermore, the lower part of the sealing body is connected to the fixed plate of the pump body, and the upper part is connected to the motor transmission device through a bearing body. The sealing body is equipped with packing, and the packing cover is fixed at the top of the sealing body to compress the packing. The pump shaft passes through the middle of the packing. Furthermore, the bearing body comprises a shaft sleeve connected to two disc bearings at the upper end of the bearing body. The shaft sleeve is fixed to the shaft by a shaft sleeve locking nut, and the upper bearing is fixed to the shaft sleeve by a bearing locking nut. The upper bearing is provided with an upper bearing cover, and the lower end of the shaft sleeve is the lower bearing. The lower bearing is installed at the bottom of the bearing body, and the lower part of the lower bearing is the lower bearing cover.

Technical protection points

High temperature molten salt vertical Suspended semi submersible sump pump, characterized by: comprising a support tube nested inside the lining tube, the upper end of the support tube is connected to an upper transmission device, the upper transmission device comprises a bearing body and a sealing body arranged in sequence from top to bottom, and the cooling chamber of the bearing body or/and the sealing body is provided with a cooling mechanism; The lower end of the support tube is connected to the pump body, and the pump cover is fixed in the middle of the pump body and the support tube. The pump shaft sleeve is located in the middle of the support tube, and the support tube is used to provide an additional length of the pump body relative to the upper transmission device. When the liquid submerges the impeller of the pump body, it can be started. The support tube's reflux effect on the high-temperature medium is used to achieve dual sealing of the bearing body and the sealing body, preventing the overflow of high-temperature hot gas.

QQ

QQ